Have a great 4th of July celebration! Our team will be taking off on Monday, July 3rd and Tuesday, July 4th and will return on Wednesday, July 5th!

Wednesday, June 28, 2023

Monday, May 1, 2023

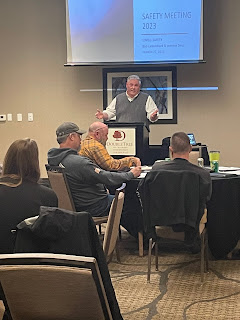

Michael Jandzinski's Safety Class in Buffalo

Lovell Safety Representative, Michael Jandzinski performs an OSHA 10 Hour Safety Class in Buffalo. At Lovell, “Safety Pays Dividends”, to the tune of 27.5% for members of Safety Group # 469 – the NYS Construction Industry Trade Group! Special thanks to our partners at the Construction Exchange of Buffalo for hosting the event!

Tuesday, April 18, 2023

EMI Guide Rail's Annual Safety Forum

Special thanks to Emmy Ingalsbe and the management team at EMI Guide Rail, LLC, for having Lovell at their annual safety forum held on March 27, 2023, at the Double Tree Hotel in Schenectady. Robert Labombard, Lovell Assistant Director of Safety and Jeanine Deyo, Lovell Regional Claims Representative participated and presented to EMI staff. Safety is what drives safety group performance and this year members of safety group #469 will be enjoying a 27.5% dividend!

Fall Protection Training for CRS

Safety is what drives safety group performance and at Lovell, we don’t just promise safety services – we deliver! Susan G. Fahmy, Vice President and Director of Safety at Lovell provides fall protection training to employees of our business partner CRS – Corporate Relocation Systems Inc.. Members of Safety Group #251 - NYS Movers, Truckers, & Warehousemen have proven that safety pays with their most recent dividend of 32.5%.

Tuesday, March 28, 2023

Congrats to Carlos Claudio

Congratulations to Lovell’s own, Carlos Claudio for completing his very first NYC half marathon! The United Airlines NYC Half Marathon returned to the streets of New York City on Sunday, March 19, 2023. The 13.1-mile journey began in Brooklyn, went over the Manhattan Bridge, headed north on the FDR Drive, zipped through Times Square (only 1 of 2 times it is closed each year), and finished in Central Park. Quite a sightseeing run through the heart of NYC!

5th Annual Safety Executives of New York Annual PDC

Susan Fahmy and Wael Khalil recently attended a safety professional development conference so that we can stay up to date on what is going on in the safety industry. The theme of the 75th annual Safety Executives of New York Annual PDC was psychosocial hazards, risks and prevention. Fun fact: Susan was a past president of SENY!

Bloodborne Pathogens & Infectious Diseases Awareness training at Jefferson Concrete Corp.

John Macvittie, Lovell Safety Consultant provides Bloodborne Pathogens & Infectious Diseases Awareness training last week to staff at Jefferson Concrete Corp. Special thanks to our business partner Jefferson Concrete Corp., the mutual commitment to loss prevention is what drives the consistent dividends in Lovell’s Workers’ Compensation Safety Groups. To date, Lovell customers have received over $1.15 BILLION in dividends.

Wednesday, March 22, 2023

Forklift Training for Vicon Industries

There’s a reason why Lovell Workers’ Compensation Safety Group’s consistently outperform the market - a working partnership with our clients to improve safety and drive down their workers’ compensation costs! Nick Lisio, Lovell Safety Consultant gets a special thank you from our partners at Vicon Industries Inc. for conducting Forklift Certification Training!

Tuesday, March 21, 2023

JC Duggan-3-15-2023

Lovell Safety Consultant, Wael Khalil conducted Forklift Certification Training on 3/15/23 at our policyholder JC Duggan Inc.’s Brooklyn location.

Safety Pays Dividends to the tune of 32.5% for those in Lovell Workers’ Compensation Safety Group #251!

Monday, March 13, 2023

Training Session for Fall Protection

Safety pays Dividends! John Macvittie, Lovell Safety Consultant conducts a half day training session on fall protection for members of the NNYBE (Northern New York Builders Exchange, Inc.). Lovell’s workers’ compensation programs are more than a certificate of insurance, coverage comes with meaningful services that help drive better performance!